There are many industries that have been affected by the COVID-19 pandemic and more recently, one of the biggest issues overall has been around supply chain shortages. Labor shortages have also been a major contributing factor to these supply challenges. The food industry and ingredients space has been hit especially hard with these problems and many ingredient companies are having trouble getting their customers the ingredients they need. There are a few reasons for these problems, such as labor, transportation delays and chemical shortages, which will be discussed in further detail below.

I was blessed with many wonderful graduate students and technicians during my career. My primary emphasis was on undergraduate education. Technicians and grad students ran the lab and kept me informed. One of those students was Christine Gianella. Without her I would never have made it through my last semester when my last three students completed their degrees. Christine also holds the distinction of being one-half of the only romance in my lab that bloomed into a marriage. Wishing Christine and Ben as wonderful marriage as I have enjoyed. I am pleased to welcome her guest blog on what she does in her day job.–RLS

The food industry always has its fair share of normal reasons for supply chain struggles: drought, poor crop yield, etc. to name a few, but the COVID-19 pandemic only served to magnify these issues. One of the first issues observed were shortages on the primary inputs that go into producing the finished ingredients. Propylene oxide is an ingredient that is used to produce modified food starch, which is a highly functional and inexpensive ingredient used in a large variety of food products. Without propylene oxide, producing modified food starch cannot be done. One of the major companies that produces propylene oxide declared “Force Majeure” meaning that they would not be able to provide ingredients as originally expected due to uncontrollable events (such as war, labor stoppages or extreme weather) that are not the fault of the any party and that make it difficult or impossible to carry out normal business.

Many companies have been led to declare force majeure because they are experiencing labor issues due to COVID-19 and are unable to produce material or, due to variable weather conditions, have had issues getting good yields out of their planted crops that eventually become the finished ingredients. So while there has not been an increased demand for modified food starch, there has been a decrease in availability due to pandemic-related issues in labor and poor/varying weather conditions compared to years past.

With the rise in popularity of meat and dairy alternatives as well as more consumers purchasing goods to be consumed in the home due to the pandemic, the hydrocolloids market has recently had a larger-than-usual demand. While these hydrocolloids are already in great demand for use in products like yogurts, ice cream, soups and sauces, there is an even larger shortage currently due to poor crop yields. Hydrocolloids like locust bean gum, tara gum, guar gum and xanthan gum are highly functional and unfortunately there are not many alternatives. The low supply is also driving up higher costs, which some companies are simply not willing to pay. Crop cycles can be long depending on the ingredient and weather patterns continue to change so we won’t know what this year’s crops will yield yet but hope to have a better idea as we get into the new year.

In addition to necessary raw materials being in short supply, across the world, there are shortages on pallets, shipping material and shipping vessels. The industry is still dealing with the fallout of the Suez Canal blockage back in the spring, which has caused a major backlog of materials and products being shipped via boat. Without pallets, it is nearly impossible to transport ingredients efficiently to various regions of the country and world.

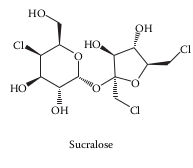

Many ingredients produced in Asia are unable to be shipped to the US or other regions due to all the shipping challenges and are declaring force majeure on all their export customers. Many of the ingredients produced in China, like sucralose for example, are not only dealing with the challenges already discussed but also government mandated energy curtailments to help address environmental concerns, which in turn leads to less production time for those ingredients in that region and globally.

Many ingredients produced in Asia are unable to be shipped to the US or other regions due to all the shipping challenges and are declaring force majeure on all their export customers. Many of the ingredients produced in China, like sucralose for example, are not only dealing with the challenges already discussed but also government mandated energy curtailments to help address environmental concerns, which in turn leads to less production time for those ingredients in that region and globally.

All these ingredient shortages have made it very difficult for both ingredient suppliers and their customers to do their jobs. As a technical services manager, I am responsible for helping my customers formulate their products and solve technical challenges therein. Of the 28 ingredient categories I have in my portfolio to offer my customers, we only are able to offer 4 of them for 2022 due to supply constraints. We are seeing similar scenarios for other ingredient suppliers as well, which makes it extremely challenging to help customers formulate their products and complete their projects necessary to get innovative products or continuous improvements to market.

I get a lot of questions around if there are alternatives to some of these ingredients but often either the alternatives are also short on supply or there is no alternative for the highly functioning ingredient they are using. This is forcing customers to either halt a project in its tracks or reformulate, which is costly, time-consuming and often requires a label change to their packaging or can force them to use a less functional ingredient. Making any of these formulation changes could alter the sensory experience and shelf life of their finished product. Some customers are even forced to stop production as they are unable to procure any of the ingredients needed to produce their finished product. Referring to the previous modified starch example, customers who were using modified food starch have started exploring native starch instead because there is slightly more supply of this ingredient, although not much more.

Because native starch is not chemically modified with propylene oxide, it becomes less functional and produces a different mouthfeel and texture depending on the application. For example, when working in the dairy/dairy alternative space, it is difficult to switch from a modified starch to a native starch because native starch does not have the same functionality as modified. It does not have good cold-water stability, water holding capacity or the same texture that modified does and is typically not able to hold up as well to the harsh processing parameters which sometimes leads to a less acceptable product.

All of these issues have also caused many of the big food manufactures to pause on innovation. We continue to hear that securing a good ingredient supply is the main focus for customers, which has been a huge shift from a support standpoint. In the past, many customers were focused on innovation to help stay relevant in the market, increase brand recognition and be a category leader but all of that has taken a backseat due to all the supply issues. Ingredient prices have increased too, and this makes it even more challenging for our customers to work on new innovation or maintain their current products. The main takeaway: being forced to reformulate existing products due to shortages means less time that can be devoted to new product innovation.

So how long will the food industry be dealing with these supply chain issues made worse by the COVID-19 pandemic? This is a hard question to answer because each ingredient has its own supply chain issues. Some experts have a more optimistic view than others and have given a time frame of 3-6 months, but many are saying that we can’t expect to see some shifts in the market until at least 2023. Many factors will determine the future supply of our ingredients market and it will be crucial that we get good yields out of the new crops being planted for this year’s supply. The good news is that tough times like these can also lead to new ways of thinking and new ways of getting creative with what is available. Food scientists are having to approach these challenges in the words of President Theodore Roosevelt: “Do what you can, with what you have, where you are.”

Christine Addington has 10 years’ experience in the food industry and is currently working as a Senior Technical Services Manager at Cargill, helping her customers formulate new products and solve technical challenges. She has been with Cargill for 4.5 years supporting the dairy, dairy alternative, and conveniences categories. Prior to Cargill, Christine worked at Dean Foods on the innovation team supporting the development and commercialization of new dairy and dairy alternative products. Before Dean Foods, she worked at Leprino Foods as an R&D Manager for 3.5 years supporting cheese product development for both domestic and international customers. Christine has an undergraduate degree in Food Science and Nutrition from Georgia Southern University and a Master’s in Food Science from the University of Georgia.

Next week: We can change our food. Who is with me? by Julie Carlson MBA, RD, LDN

Special thanks to Dr. Ronald Pegg for assistance with chemical structures

We’re spoiled. We can go fishing and not mind catching two kinds of fish, or two sizes, but we expect what we buy to be the same every time. It shows how complex our foods have become, and how we’re addicted to their precise sameness. I’m more concerned with safety, cost and nutrient content, and less with image, appearance and being “best,” but I know I’m in the minority.

LikeLike

It all goes back to expectations. Companies provide us with choices. Marketers convince us to try new products. Specific preferences become wants which turn into needs when not on the shelves. It becomes a vicious cycle. Who is to blame?

LikeLike

Too many of us are too affluent to know how to adapt, and even be proud of it. As in a Tom Lehrer song, “the water tasted foul for weeks so we had to make do with gin.”

LikeLike

Or the food is not very good and there’s not enough of it.

LikeLike

Interesting what a difference a single little molecule can make. I hear similar observations about how disruptive a change in ingredient availability can be from a couple of colleagues who work in food labeling. Complex systems don’t always respond well to sudden changes.

LikeLike